Infrared for glass tempering

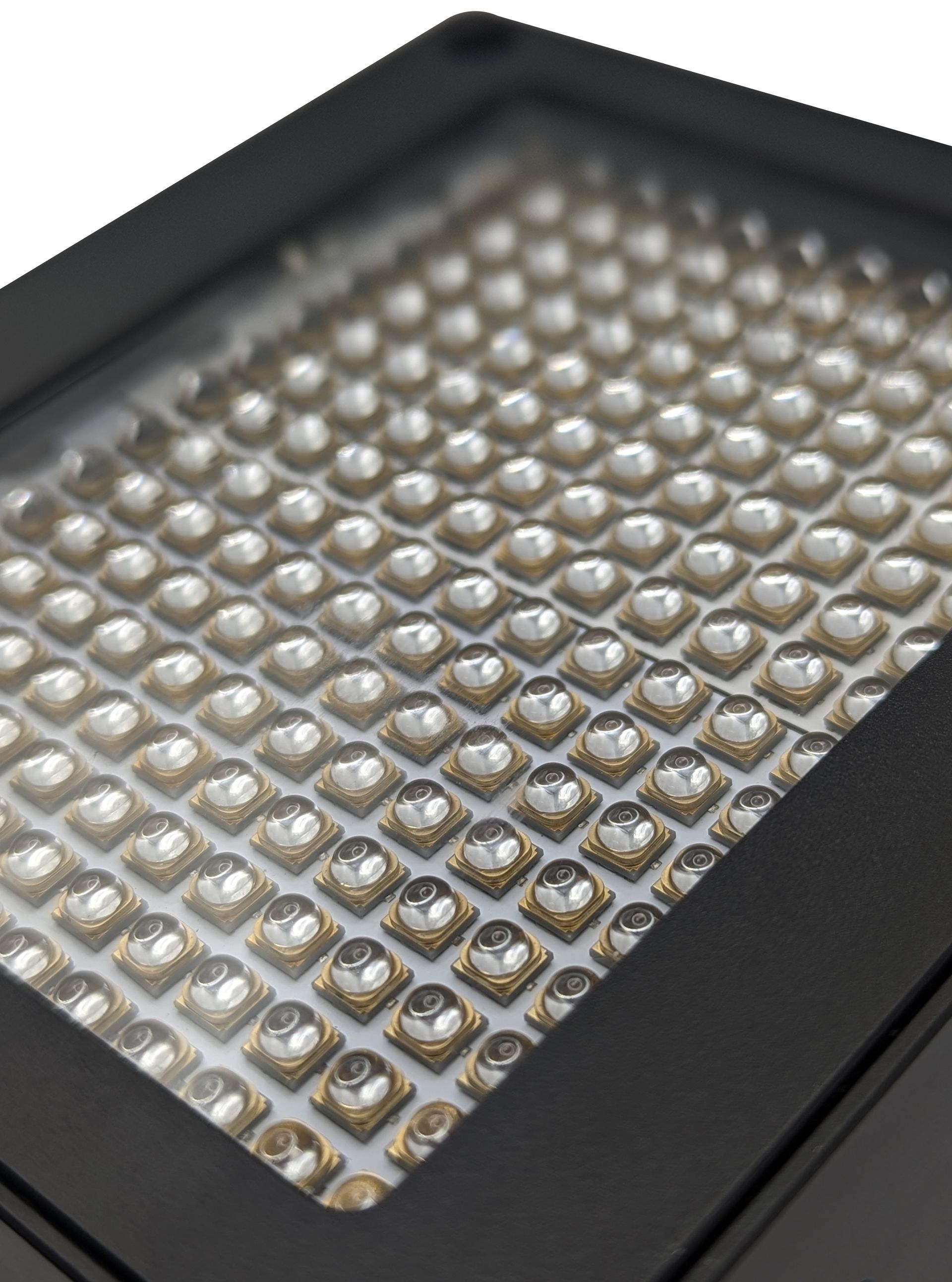

As technology advances, new methods are constantly being introduced to enhance industrial processes. One such innovation in the glass industry is the use of infrared for glass tempering.

Enhanced Efficiency: By harnessing infrared radiation, glass tempering is made more efficient and reliable. Infrared heaters provide a focused and uniform heat distribution, ensuring consistent heating across the glass surface. This eliminates hotspots and cold spots, leading to higher productivity and reduced material waste.

Superior Strength: Infrared heating promotes uniform expansion and contraction of glass during the tempering process. This eliminates stress points, making the glass more durable and resistant to breakage. As a result, tempered glass becomes a safer and more reliable option for various applications, from automotive to architectural.

Versatility: Infrared technology offers flexibility when it comes to tempering various types of glass. Whether it's clear, tinted, coated, or low-E glass, infrared heaters can be adjusted to accommodate different thicknesses and compositions. This versatility allows manufacturers to meet diverse customer demands and expand their product range.

Environmentally Friendly: Infrared heating for glass tempering is an eco-conscious choice. Compared to conventional methods, such as convection heating, infrared technology requires less energy and reduces greenhouse gas emissions. By adopting this sustainable approach, your business can contribute to a greener future.

Cost-Effective: Adopting infrared technology for glass tempering can yield long-term cost savings. With improved efficiency, reduced material waste, and enhanced durability, businesses can achieve higher production rates, lower rejection rates, and ultimately increase their profitability.